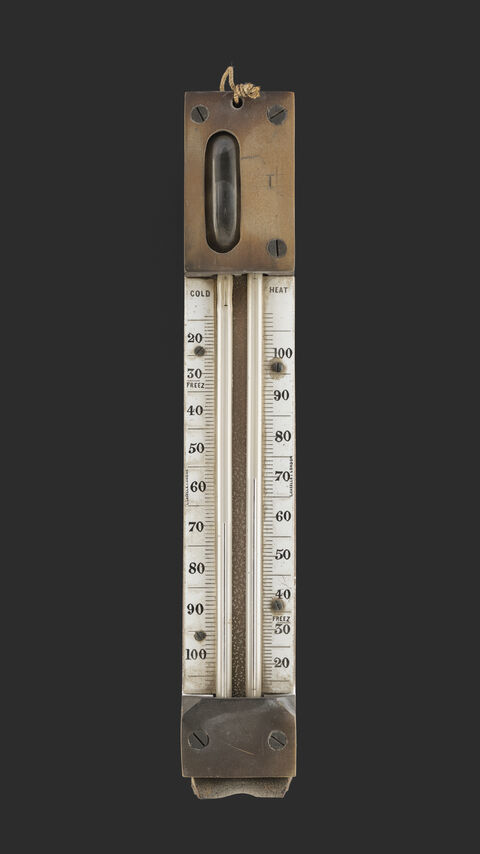

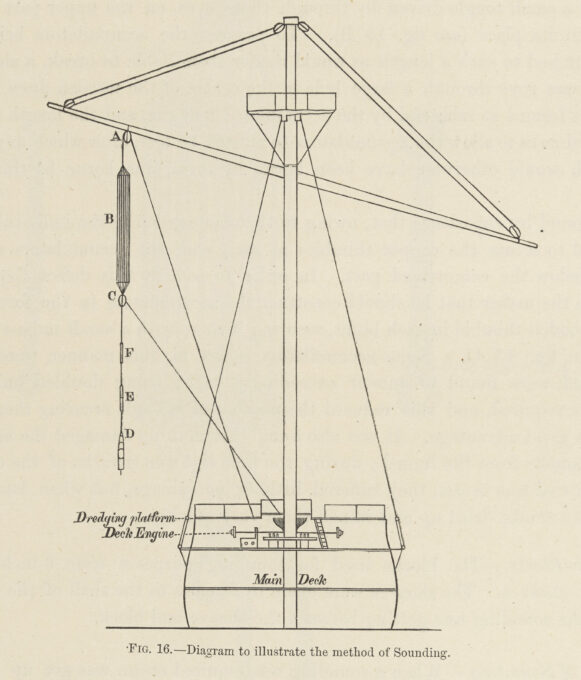

One of the great difficulties of 19-century ocean science was that the deep sea could not be directly observed. Knowledge of the ocean depended on the movement of instruments to and from the ship, floating at the ocean surface, and the ocean depths below.

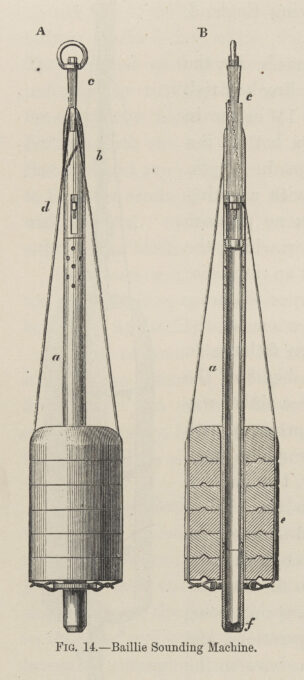

Deep-sea sounding is one of Challenger’s greatest contributions to oceanography. A process of measuring the depth of a body of water, sounding was carried out at each of the 362 stations, making visible the great depths, broad plains, and mountain ranges of the Atlantic Ocean, Pacific Ocean, and the Southern Ocean basins.